Polystyrene Sheet Pressing from Pellets (13 mm)

2 min read

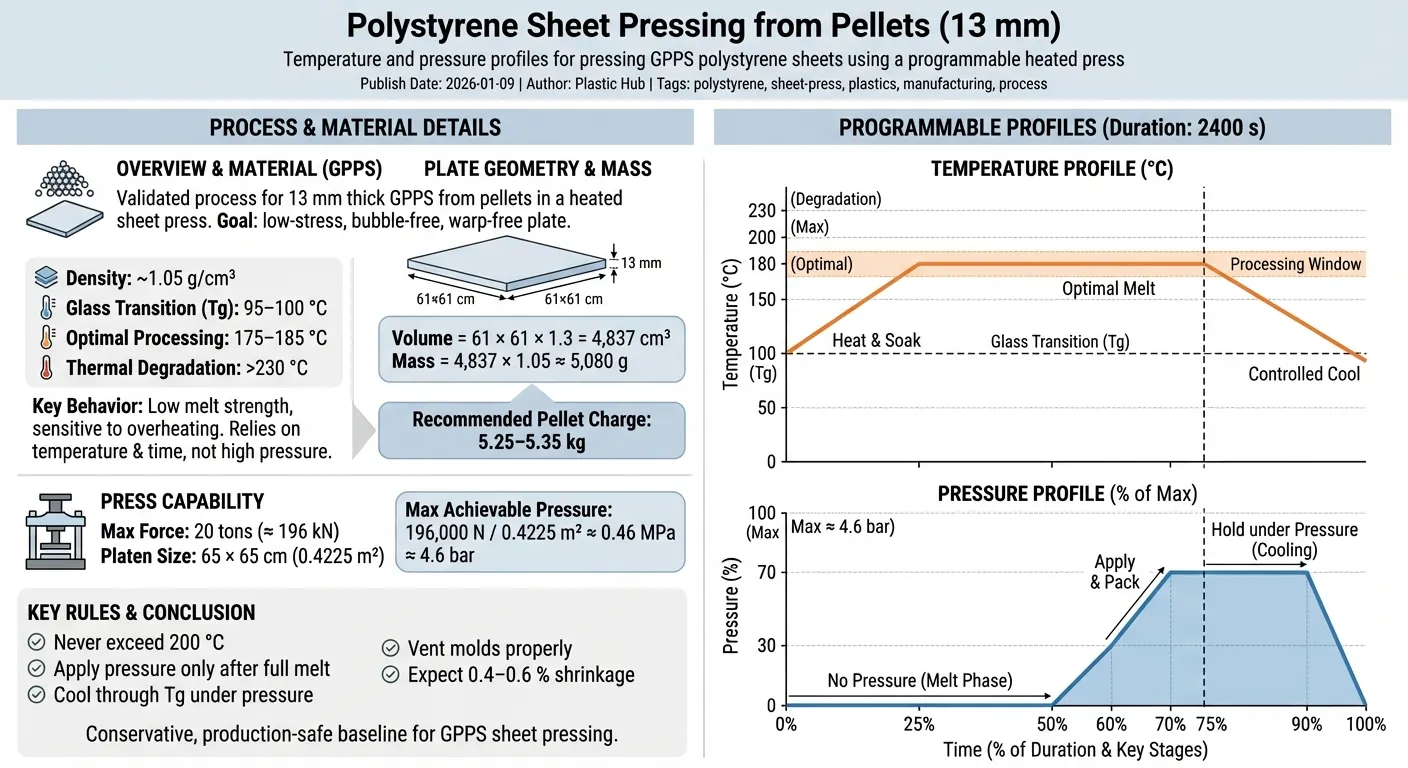

By Plastic Hub February 1, 2026Temperature and pressure profiles for pressing GPPS polystyrene sheets using a programmable heated press

Overview

This article documents a validated process for pressing 13 mm thick GPPS polystyrene sheets from pellets using a heated sheet press with fully programmable temperature and pressure profiles.

The goal is a low-stress, bubble-free, warp-free plate, suitable as a baseline recipe for further optimization.

Material Properties (GPPS)

- Density: ~1.05 g/cm³

- Glass transition (Tg): 95–100 °C

- Optimal processing window: 175–185 °C

- Thermal degradation: >230 °C

- Key behavior: low melt strength, sensitive to overheating

Polystyrene relies primarily on temperature and time, not high pressure, for good inter-pellet fusion.

Plate Geometry & Mass

- Final size: 61 × 61 cm

- Thickness: 13 mm (1.3 cm)

Mass calculation

Volume = 61 × 61 × 1.3 = 4,837 cm³

Mass = 4,837 × 1.05 ≈ 5,080 gRecommended pellet charge: 5.25–5.35 kg

Press Capability

- Maximum force: 20 tons ≈ 196 kN

- Platen size: 65 × 65 cm (0.4225 m²)

Maximum achievable pressure

196,000 N / 0.4225 m² ≈ 0.46 MPa ≈ 4.6 barController Scaling Model

x = 0–1000→ 0–100 % of total durationmax = 200→ 200 °C = 100 %

Examples:

y = 900→ 180 °Cy = 450→ 90 °C

Temperature Profile (Safe / First Run)

{

"duration": 2400000,

"max": 200,

"controlPoints": [

{ "x": 0, "y": 500 },

{ "x": 250, "y": 900 },

{ "x": 600, "y": 900 },

{ "x": 750, "y": 900 },

{ "x": 1000, "y": 450 }

]

}Pressure Profile

{

"max": 100,

"controlPoints": [

{ "x": 0, "y": 0 },

{ "x": 500, "y": 0 },

{ "x": 600, "y": 30 },

{ "x": 700, "y": 70 },

{ "x": 900, "y": 70 },

{ "x": 1000, "y": 0 }

]

}Key Rules

- Never exceed 200 °C

- Apply pressure only after full melt

- Cool through Tg under pressure

- Vent molds properly

- Expect 0.4–0.6 % shrinkage

Conclusion

This document provides a conservative, production-safe baseline for pressing GPPS polystyrene sheets from pellets using a programmable press.